Remanufactured Engines

Remanufactured Engines & Gearboxes

When your Mini's engine has reached the end of its life and requires remanufacturing, it's often the case that the gearbox is in a similar state. Given that the engine and the gearbox in a Mini share the same oil, it's not advisable to pair a high-quality remanufactured engine with an old gearbox. This could compromise the reliability and reduce the life expectancy of your engine.

To address this, we offer full units comprising of a Mini Sport remanufactured engine and a Mini Sport remanufactured gearbox, fully built up with a new clutch assembly. Crafted to the highest standards, these units promise to deliver trouble-free motoring for years to come.

Find your perfect Mini Engine!

Engine Blueprinting: Precision Engineering for Perfection

We're thrilled to introduce Engine Blueprinting to our reconditioning process. This meticulous service involves perfectly matching the tolerances of every engine, cylinder head, and gearbox we produce. The result? Harmonised components that operate in perfect unison, delivering enhanced performance, reliability, and efficiency for your classic Mini.

Discover how Engine Blueprinting elevates your Mini's performance to new heights.

Remanufactured Engines

Experience increased reliability, extended service life, and enhanced performance with our remanufactured engines. Each engine is meticulously rebuilt to ensure it meets the highest standards of quality and performance, providing you with the peace of mind that your Mini is powered by an engine that's as good as new.

Explore our full range of engines & find the perfect match.

Choose your Engine

Discover Mini Sport's Remanufacturing Process!

Remanufactured Cylinder Heads

Our remanufactured cylinder heads have been a popular choice for many years, offering a high-quality, reasonably priced solution for your Mini. Each cylinder head is carefully reconditioned to meet or exceed original specifications, ensuring optimal performance and longevity.

Bring your Cylinder Head to us for Remanufacturing!

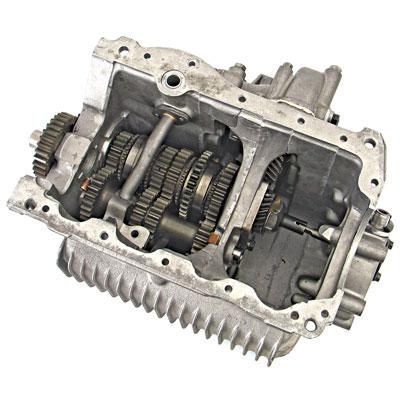

Remanufactured Gearboxes

Each gearbox we remanufacture is dismantled and thoroughly cleaned using the latest environmentally friendly processes. Every component is inspected for wear and damage, with all non-conforming parts discarded and replaced. The gearbox is then reassembled using all new bearings, shafts, and baulk rings. The differential is also fully overhauled, including pins, pinions, and bearings.

We also offer remanufacturing services for all types of early remote 3 synchro gearbox Minis. Due to the shortage of old core units, it may be necessary to rebuild your own gearbox.

Please note, all remanufactured components are supplied on an exchange basis. A surcharge will be levied until serviceable old units are supplied. Depending on the availability of old core units, we may need your own units to work on.

We are here to offer help & advise for all your Mini needs!