When it comes to enhancing your Mini's performance, your Mini's Brakes are a crucial aspect that demands attention. Most upgrades focus on the front end, ensuring your Mini can handle the demands of modern driving while maintaining its classic charm. Let's dive into the details of our recent brake enhancements, ensuring every component is optimised for safety and performance.

Brake: Optimising Your Mini's Stopping Power

Rear Brakes and Handbrake Quadrants

We started by replacing the rear brake backplates with Mini Sport pre-built replacement rear brakes. These units come with Mini Sport alloy Minifin replica brake drums, which significantly improve brake shoe cooling and match the Cooper S/Rover rear drum offset.

To ensure the longevity and smooth operation of the handbrake quadrants, we used 3-in-One White Lithium aerosol grease. This product not only protects the quadrants but also keeps the handbrake cable well-lubricated.

Caliper and Hose Installation

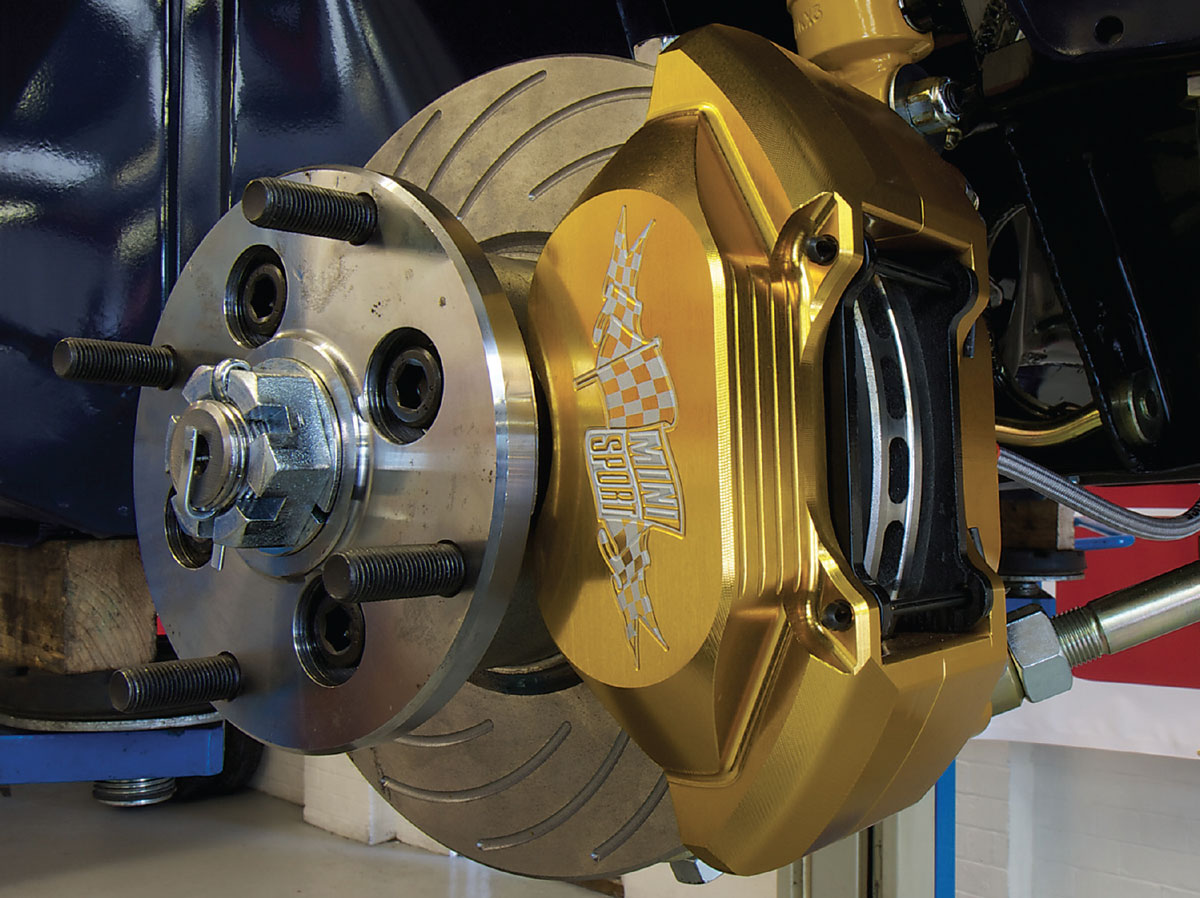

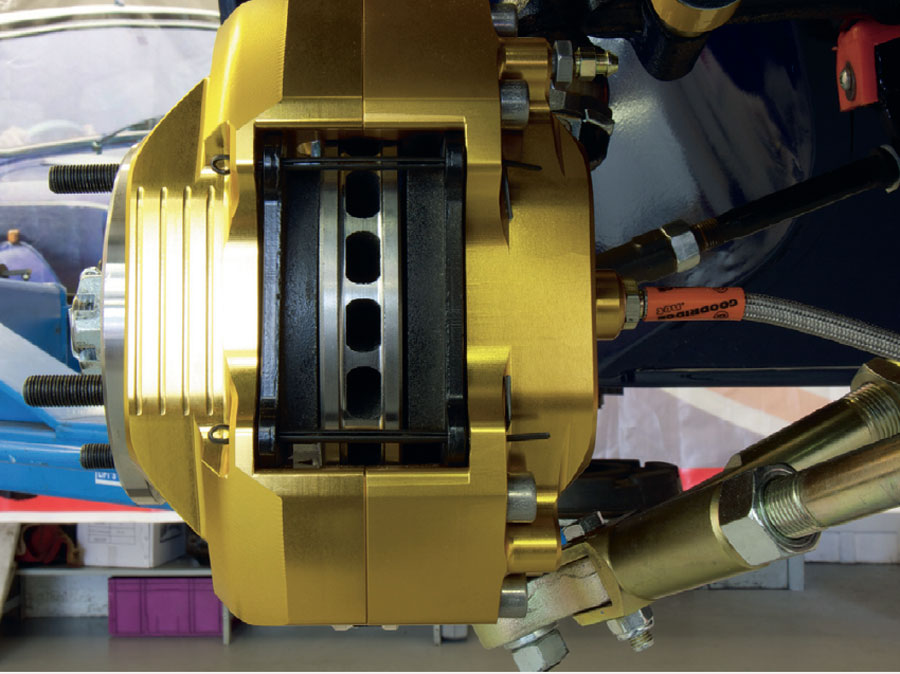

Using Aluminium Calipers

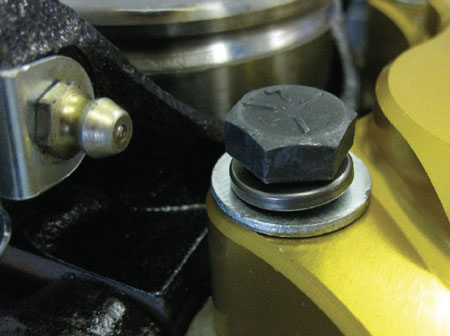

When using aluminium calipers, it's important to include both a flat washer and a spring washer when bolting it to the hub. This spreads the load effectively. In contrast, the standard cast iron calipers (like the heavy AP items) do not require an extra flat washer. We utilised Mini Sport's alloy four-pot calipers for superior braking power.

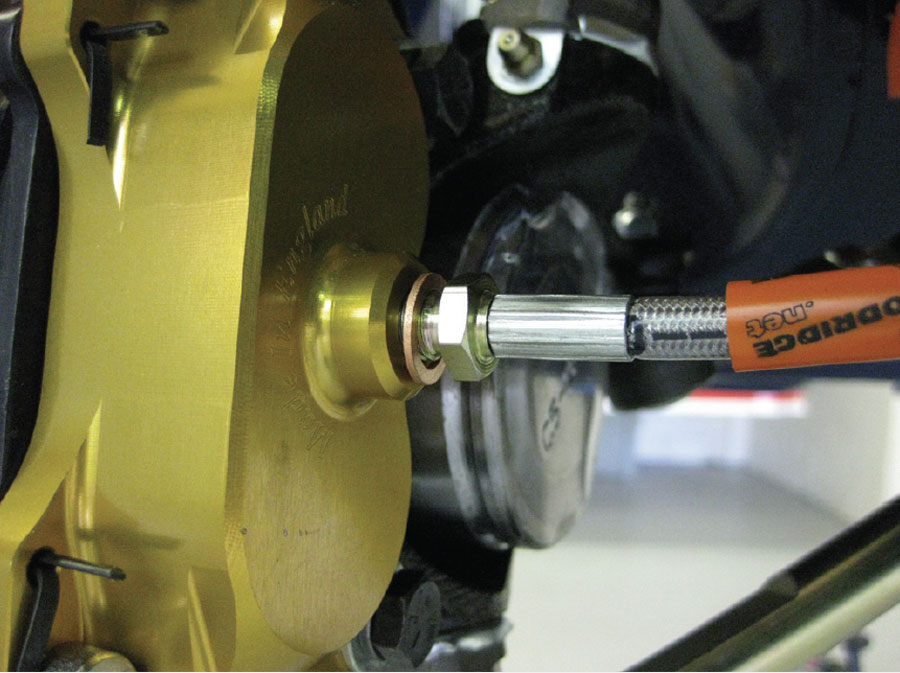

Connecting Steel Braided Hoses

Goodridge steel braided hoses were chosen to connect the calipers to the front subframe. These hoses require a copper washer, which should be replaced if the hose needs to be undone. This ensures a reliable and leak-free connection.

Securing Hoses to the Subframe

The inboard end of the Goodridge caliper hoses is secured with a plain nut and a special anti-shake washer, locking it to the front subframe. This type of aggressive lock washer is essential here. To avoid twisting stresses, always fit the hoses to the calipers first, then to the subframe.

Vented and Grooved Rotors

The Mini Sport vented and grooved rotors can be mounted in either direction. When the grooves point with rotation, more air is pulled into the pad, enhancing cooling but increasing noise. If the grooves point the other way, brake noise is reduced, but cooling is less effective in motorsport conditions.

By following these detailed steps, you can ensure your Mini's braking system is both reliable and effective, ready to meet the demands of any driving scenario. Remember this is just a guide, if you are unsure about any steps involved in this process contact a trusted professional. The Mini Sport team can be contacted for advice, recommend nations or to book an appointment. Get in touch today!

Want to read Keeping Your Mini Alive 6th Edition Magazine? Download the PDF here

Don't miss out on the rest of the Bogus 2 Series!

This blog series is your go to for a guide to taking your Mini from a bare shell to a road-worthy classic. Check out the rest of the series for tips and advice from our Mini Experts for every stage of your Mini restoration!

Throughout the restoration process, using high-quality products ensures durability and performance. Visit our website to find all the parts mentioned in this guide.

If you need any help or expert advice, don't hesitate to contact us. Happy restoring!

This guide is meant to provide general information and a step-by-step approach to restoring your Mini's front subframe and suspension. It is always recommended to contact a trusted professional if you are unsure about any part of the process or lack the necessary tools and experience. Safety should be your top priority.